More precious than stainless steel, too

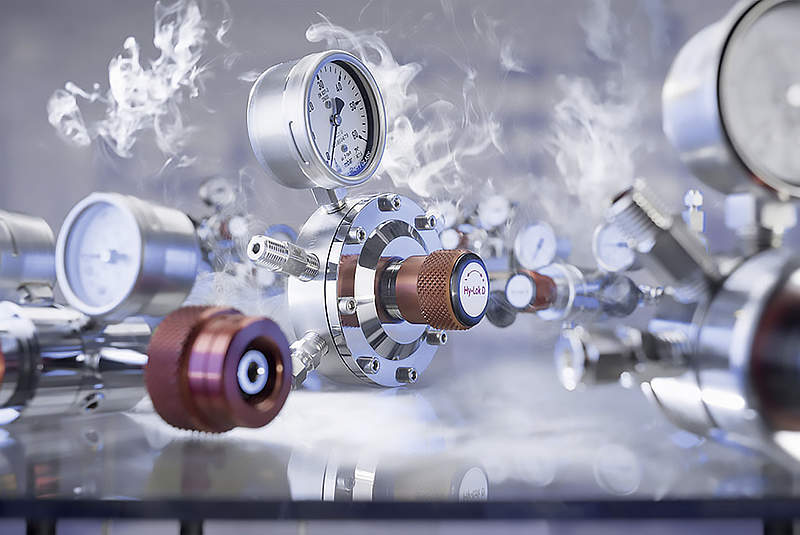

Hy-Lok's stainless steel portfolio includes screw connections, valves, fittings and seals. Throughout the world the company stands for highest quality and precision. Hy-Lok D, a HANSA-FLEX affiliate, has been distributing South Korean quality products since 1998. They are used wherever high-purity, corrosive liquids and gases exclude the use of carbon steel components. Hy-Lok D has a highly qualified field service to ensure that customers always receive the right products for any complex challenges.

At first glance, the Hy-Lok and HANSA-FLEX products look very similar: screw fittings, control and shut-off valves, ball valves and hoses. This impression is deceptive, however. "We do everything but hydraulics," explains Wolfgang Groh, Business Division Manager at Hy-Lok D. This is because - while hydraulic oil behaves well as a medium and does not attack pipelines - Hy-Lok products have completely different requirements. Aggressive or explosive gases and liquids such as ammonia, hydrogen sulphide, hydrogen, acids and alkalis flow regularly through Hy-Lok D's customers' pipelines, as do high-purity media. These can be found in the chemical and petrochemical industries, in plant engineering, but also in measurement, control and analysis technology and laboratories.

No project is routine

Although Hy-Lok D can supply its customers almost entirely from its standard range, there are hardly any standard projects and standard applications. Above all, the sales staff need to ask questions to find out what the customer's requirements are. This is the only way to ensure reliable product selection. Although around 90 percent of the fittings and valves supplied are made of stainless steel, the sealant materials also need to withstand the stresses. For example, when ammonia flows through a pipe, a valve must not be sealed with a fluoro-elastomer such as FKM, but with an EPDM or PTFE sealing material. In addition, extremely high-quality alloys such as Hastelloy or Monel, which are even more resistant than stainless steel, are sometimes also required for the other products. For this reason, highly qualified technicians and engineers are deployed in the field to advise customers on site. However, the engineering and installation planning are done by the customer, although if Hy-Lok D detects planning errors that would cause unnecessary costs or dangerous situations, the Hy-Lok experts draw attention to them. After all, the focus is always on the optimum result as the basis for long-term cooperation.

Oil and gas, chemicals and petrochemicals

Stainless steel products such as those supplied by Hy-Lok D are indispensable in oil and gas production, as well as in the chemical and petrochemical industries. Pipelines with outer diameters between one and 50 mm are not suitable for the large volume transport of fluids and gases, but Hy-Lok products are in great demand in the associated systems, measurement, control and analysis technology, seal gas supplies or sampling systems. These can be used in a pressure range from high vacuum to 690 bar overpressure and temperature ranges between minus 200 and plus 650 degrees Celsius. Stainless steel pipes are also required for high-purity gases and the separation of undesirable impurities such as hydrocarbons. Despite their small diameters, the dimensions of the systems in which they are used are sometimes impressive, as is the measuring and control technology in plant construction. When it comes to precision, analytical laboratories rely on Hy-Lok products - for example in gas chromatographs or mass spectrometers.

Premium quality

In view of its safety-related sensitive areas of application, top quality is a must for Hy-Lok. Naturally, the products therefore have the relevant approvals and certificates, and comply with standards such as the Pressure Equipment Directive and the ATEX directive for explosion protection. In addition, they are well below the limit values of the TA Luft air-quality regulation, which has been proven by tests in accordance with the internationally recognised ISO 15848 standard. This is also essential, because in the case of toxic and explosive substances it is important that they cannot escape. When used in analysis systems, however, it is important that nothing can either escape or penetrate the system, which would falsify measurement results. This is why numerous laboratories in industry and science rely on Hy-Lok components.

An extensive training programme

In addition to advice on selecting the most suitable products, Hy-Lok D also supports its customers with an extensive training programme. In seminars and workshops, the company imparts knowledge on product selection and safe component assembly. Although HANSA-FLEX and Hy-Lok D products are usually applied in very different industries, there are also products from the HANSA-FLEX product range that are highly relevant for Hy-Lok. These include metal, Teflon and industrial hoses. Here Hy-Lok makes use of the synergy potentials offered by a cooperation with its affiliate company. The training programme of the International Hydraulics Academy (IHA) also covers these product areas.

+49 4207 6994-0

+49 4207 6994-40